Flexibility makes the difference

As a solution partner, Acker faces up to a host of different challenges, be it adaptation of the structure of a warp-knitted fabric or a completely new, complex solution. In cooperation with our clients or completely autonomously, our team devises suitable solutions quickly and reliably.

In the process, our clients benefit from the wide-ranging options offered by our machinery, but also from the high levels of training and professional qualification of our employees. The machines installed at our plant in Seligenstadt enable us to do everything from yarn preparation through warp-knitting and dyeing to a wide spectrum of innovative finishing techniques, all “under a single factory roof”.

Ahead of our time

Acker’s innovative technical solutions already fulfil the requirements of tomorrow, resulting in customer-oriented solutions for a product base that can be adapted to different customer demands promptly and with a minimum of effort. At the same time, visual surface effects, technical properties and environmental compatibility are all criteria of equal importance both in the construction and in the launch of new Acker products.

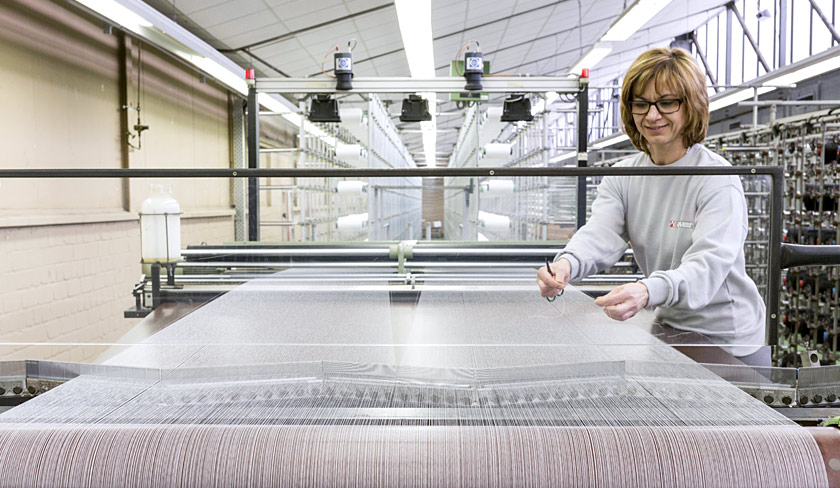

“Well warped is half knitted”

Warping is the first step of the production process at Acker. With great precision, a multitude of threads – what's called the “yarn sheet” – are spooled onto section warp beams that are then loaded into the warp-knitting machines of the subsequent process. Uniform preparation of the material is absolutely essential if the warp-knitted fabric is to be of outstanding quality. This is why all threads of the yarn are subjected to an intensive incoming inspection. We work with modern, computerised warping machines with a capacity of 120 t/month.

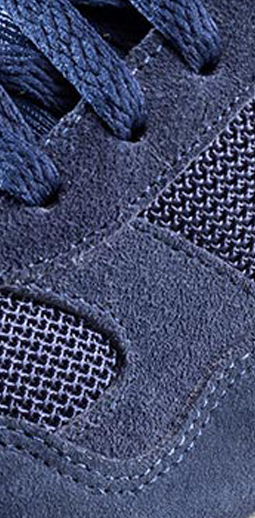

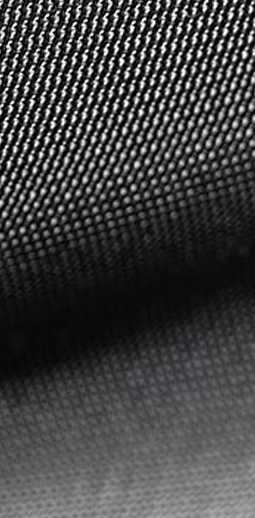

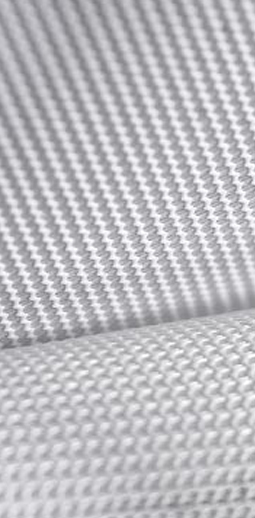

Custom warp-knitting to fulfil every customer's wish

We manufacture high-quality textiles for example velour made from polyester, polyamide and special-purpose yarns. To this end, we have more than 50 units capable of providing our customers with a variety of warp-knitting processes. In order to keep constant checks on the quality of the product, the high-performance machines are equipped with laser-assisted 100% control. Thanks to our pool of state-of-the-art warp-knitting machines, we are able to respond to any wish our customers may have. Together with our experienced employees, we work on new structures of warp-knitted fabrics or adapt existing basic patterns to new requirements.